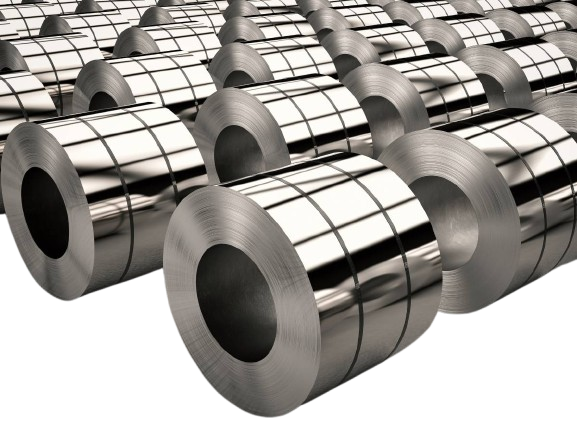

Hot Rolled Coils

Description: Hot rolled coils are flat products made from steel that are produced by rolling heated steel slabs or billets at high temperatures. This process allows the metal to be shaped into coils while it’s still in a malleable state.

Characteristics:

- Surface Finish: Typically has a rough, scaly surface due to oxidation at high temperatures.

- Thickness: Available in a range of thicknesses, usually from 1.2 mm to 25 mm.

- Strength: Offers good tensile strength and is often used for structural applications.

- Applications: Commonly used in construction, automotive manufacturing, and in the production of pipes and tubes.

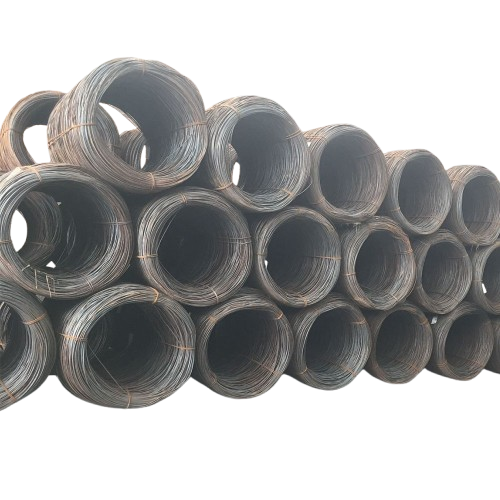

Wire Rolled Coils

Description: Wire rolled coils, also known as wire coils, are produced by drawing hot rolled steel into wire form. This wire is then wound into coils, making it easy to handle and transport.

Characteristics:

- Diameter: Can vary widely, typically ranging from 0.5 mm to several millimeters.

- Surface Finish: Generally has a smoother finish compared to hot rolled coils, depending on the drawing process.

- Strength and Flexibility: Offers a good balance of strength and flexibility, making it suitable for various applications.

- Applications: Widely used in manufacturing wire products, fasteners, construction materials, and in the automotive and electronics industries.

Both types of coils play crucial roles in various industries, and understanding their properties can help in selecting the right materials for specific applications. If you need more details or specific aspects, let me know!